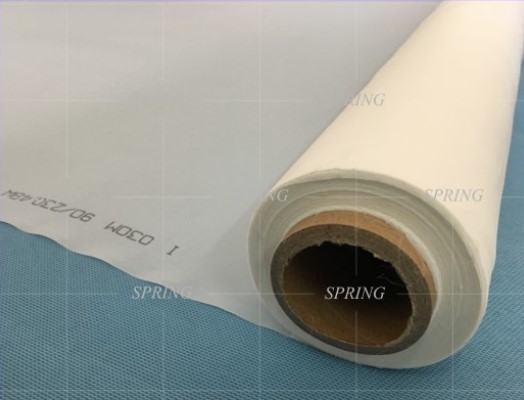

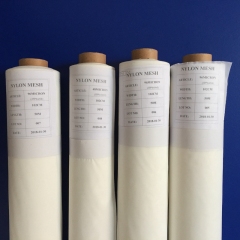

Nylon filter mesh

Description

Description

50 Micron to 2000 Micron Nylon Filter Mesh for Aquaculture

| Introduction: The Nylon Screen for Filter for Aquaculture also called nylon filter mesh, nylon mesh, polyamide mesh, Shrimp farm mesh, fish farm mesh, nylon net, nylon screen mesh, nylon filter, which is made from 100% Nylon monofilament wire. With wear resistance, good tensile strength, and flexibility, etc., it’s widely used in varies areas and industries. Shanghai SPRING nylon mesh with FDA approval can meet all the food filtration request. Such as the nylon screen mesh used for shrimp farm, fish farm, etc., under sea water to protect the living aquatic resources. SPRING can provide you with even mesh opening and even yarn diameter mesh to satisfy the high quality demand customers’ request. Also the mesh can be provided different width or shapes under request. Such as Nylon mesh belt, Nylon Screen mesh disc, mesh bags, nylon mesh sleeve, etc. |

|

Features of SPRING nylon mesh:

- Good Wear Resistance

- Good tension strength

- Long service life

- Good Alkali-resistance

- Renewable usage

- Anti-static

- Even holes

- New material woven

- Smooth surface

- Good packing

- Fast delivery

- Excellent after-sales service

- Quick response

Tips for how to choose correct nylon filter mesh:

Nylon screen mesh is alkali resistance, therefore for acid, formic acid and other erosion liquid is not good choice with nylon mesh. If acid liquid, we suggest you choose the polyester screen mesh. Avoid light for the nylon mesh stock as UV light has little impact on the mesh. If we need to used for food filter, new material with FDA approval is very important to make sure the food safe. Even mesh opening is very important. Heat setting is very important step for the nylon screen net’s production.

Specification:

| Type | Wave | Mesh/CM | Mesh/inch | Wire dia | Mesh opening | Open Area | Thickness |

|---|---|---|---|---|---|---|---|

| PA-4/1950 | PW | 4 | 10 | 550 | 1950 | 61 | 1096 |

| PA-5/1500 | PW | 5 | 13 | 500 | 1500 | 56 | 998 |

| PA-6/1267 | PW | 6 | 15 | 400 | 1267 | 58 | 796 |

| PA-7/1079 | PW | 7 | 18 | 350 | 1079 | 57 | 691 |

| PA-8/900 | PW | 8 | 20 | 350 | 900 | 52 | 697 |

| Thickness | PW | 9 | 24 | 250 | 861 | 60 | 492 |

| PA-10/750 | PW | 10 | 25 | 250 | 750 | 56 | 494 |

| PA-12/533 | PW | 12 | 30 | 300 | 533 | 41 | 590 |

| PA-14/514 | PW | 14 | 35 | 200 | 514 | 52 | 391 |

| PA-16/425 | PW | 16 | 40 | 200 | 425 | 46 | 393 |

| PA-18/356 | PW | 18 | 45 | 200 | 356 | 41 | 395 |

| PA-20/300 | PW | 20 | 50 | 200 | 300 | 36 | 396 |

| PA-24/267 | PW | 24 | 60 | 150 | 267 | 41 | 292 |

| PA-28/207 | PW | 28 | 70 | 150 | 207 | 34 | 295 |

| PA-30/213 | PW | 30 | 76 | 120 | 213 | 41 | 230 |

| PA-32/213 | PW | 32 | 80 | 100 | 213 | 46 | 186 |

| PA-36/178 | PW | 36 | 90 | 100 | 178 | 41 | 189 |

| PA-40/150 | PW | 40 | 100 | 100 | 150 | 36 | 192 |

| PA-44/127 | PW | 44 | 110 | 100 | 127 | 31 | 195 |

| PA-48/128 | PW | 48 | 120 | 80 | 128 | 38 | 150 |

| PA-56/119 | PW | 56 | 142 | 60 | 119 | 44 | 96 |

| PA-59/109 | PW | 59 | 150 | 60 | 109 | 42 | 110 |

| PA-64/96 | PW | 64 | 163 | 60 | 96 | 38 | 116 |

| PA-72/89 | PW | 72 | 183 | 50 | 89 | 41 | 90 |

| PA-80/75 | PW | 80 | 203 | 50 | 75 | 36 | 93 |

| PA-88/71 | PW | 88 | 224 | 43 | 71 | 39 | 70 |

| PA-96/61 | PW | 96 | 244 | 43 | 61 | 34 | 74 |

| PA-100/57 | PW | 100 | 254 | 43 | 57 | 32 | 75 |

| PA-104/53 | PW | 104 | 264 | 43 | 53 | 31 | 76 |

| PA-110/48 | PW | 110 | 280 | 43 | 48 | 28 | 78 |

| PA-120/40 | PW | 120 | 305 | 43 | 40 | 23 | 80 |

| PA-130/34 | PW | 130 | 330 | 43 | 34 | 19 | 83 |

| PA-140/33 | PW | 140 | 355 | 38 | 33 | 22 | 73 |

| PA-150/28 | TW | 150 | 380 | 39 | 28 | 17 | 75 |

| PA-157/25 | TW | 157 | 400 | 39 | 25 | 15 | 76 |

| PA-165/30 | TW | 165 | 420 | 30 | 30 | 25 | 54 |

| PA-200/21 | TW | 200 | 500 | 30 | 21 | 17 | 56 |

| PA-240/3 | TW | 240 | 600 | 39 | 3 | 0.5 | 68 |

Send your message to us